Factories in India are getting smarter. Thanks to new technology, machines are no longer working alone. They are now connected, talking to each other, and sharing information in real time. This is possible because of something called industrial IoT—which stands for Industrial Internet of Things. In this blog, we’ll explore how industrial IoT solutions in India are changing the way factories work and helping the country grow as a manufacturing leader.

What Are Industrial IoT Solutions?

Before we dive into how they help, let’s understand what they are.

Industrial IoT solutions in India are smart systems that connect machines, sensors, computers, and people in factories. These systems collect data from machines, send it to the cloud (online storage), and use it to make better decisions.

For example, a machine might tell the system:

“I’m overheating.”

“I need maintenance soon.”

“I’ve made 1,000 parts today.”

With this kind of data, factory managers can see what’s working, what’s not, and what needs attention.

How Do Industrial IoT Solutions Work?

Step 1: Collect Data

Sensors are attached to machines. These sensors track things like temperature, speed, energy use, and more.

Step 2: Send Data to the Cloud

The information collected is sent to the cloud where it is stored safely.

Step 3: Analyze and Take Action

Factory managers or software programs analyze the data and take action. If something is wrong, a message or alert is sent.

This is how industrial IoT solutions in India help factories fix problems before they become serious.

Why Are They Important for India?

India wants to become a global manufacturing hub. To do that, factories need to be fast, smart, and cost-efficient. Industrial IoT solutions in India make this possible by improving how factories work without spending a lot of money on new machines.

Real-Life Example: A Packaging Factory in Noida

A packaging factory in Noida uses industrial IoT solutions in India to track the health of their machines. Every machine has sensors that check how fast it is working and whether anything is wrong.

When a machine slows down or shows signs of damage, the system sends an alert. A worker gets a message on their phone:

“Machine 4: Speed below normal. Check for belt wear.”

The worker can act quickly, fix the issue, and avoid a costly breakdown.

Benefits of Industrial IoT Solutions in India

Better Productivity

Factories can produce more in less time. With real-time updates, managers can fix issues on the spot and keep machines running.

Lower Costs

By spotting problems early, companies save money on repairs and avoid shutting down the whole factory.

Improved Quality

By spotting problems early, companies save money on repairs and avoid shutting down the whole factory.

Safer Workplaces

Some industrial IoT solutions in India help keep workers safe by warning them about hot machines, gas leaks, or other dangers.

Smarter Decisions

Managers get live data, charts, and reports. They can use this information to make smart choices that improve how the factory runs.

Why Are Indian Companies Adopting This Technology?

Many Indian companies are choosing industrial IoT solutions in India because:

- The cost of sensors and cloud storage has gone down

- Internet access is now available in more locations

- Even small and medium factories want to stay competitive

- Government programs like “Make in India” support tech upgrades

From automobile plants in Chennai to textile mills in Ludhiana, factories across the country are going digital.

The Future of Smart Manufacturing in India

As more factories adopt industrial IoT solutions in India, we’ll see new features like:

- AI (artificial intelligence) predicting machine failures

- Voice control systems for workers

- Robots that take action based on sensor data

- Real-time updates shared across factories in different cities

These tools will not only boost production but also reduce waste and energy use.

Easy Integration with Other Smart Tech

One great thing about industrial IoT solutions in India is that they work well with other technologies, like:

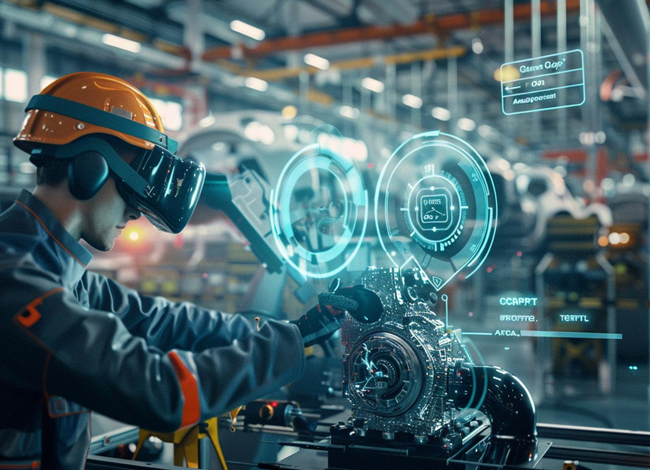

- AR (Augmented Reality): Show maintenance tips over real machines

- 5G: Send data faster between machines and cloud systems

- Big Data: Analyze huge amounts of factory information in seconds

Together, these systems create a powerful and smart factory environment.

Final Thoughts

Industrial IoT solutions in India are doing more than just connecting machines. They are helping factories run better, produce more, and stay safe. Whether it’s a large auto plant or a small furniture shop, this technology is helping businesses grow and compete on a global level.

By connecting the dots between machines, people, and data, industrial IoT solutions in India are leading the way toward a future where factories are not just places of hard work—but places of smart work.

India is on the move, and the smart factory revolution is already underway.